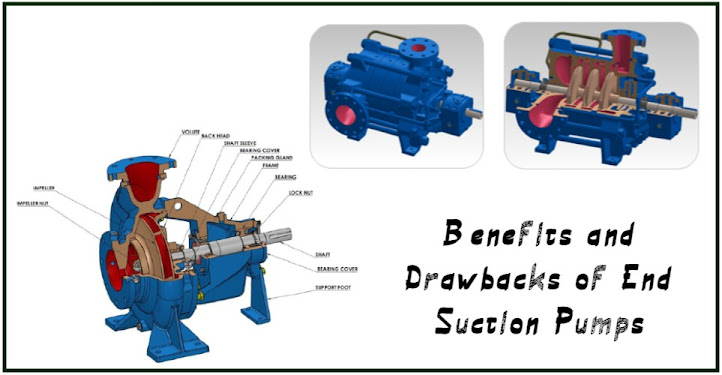

An end suction pump is a type a centrifugal pump that only has one impeller. The suction comes from one side and the discharge of the fluid comes at the top. The fluid that is pumped increases in velocity as it passes through the impeller. And the diffusion converts high velocity into high pressure before it exits the pump. These pumps can be used to move a wide variety of liquids like corrosive chemicals or high-temperature viscous oils. End suction pumps can be made using anything from plastic to standard iron to hardened iron or even stainless steel depending upon the application it is used for.

Let us study the benefits and drawback of end suction pumps.

Benefits:

Simple design

These pumps have a very simple design with only a few moving parts. They do not use any valves either. Due to its simplicity, these pumps are not difficult to maintain. To get the best quality end suction pumps in India log on to flowmore pumps.

Very low initial cost

You do not need to incur a large initial cost when getting these pumps. They are a much more economic option than horizontal split-casing pumps. Also, when you consider the output to the amount spent, these pumps prove to be highly advantageous.

Do not take up a lot of space

These pumps have compact designs. The only have one impeller which is used to move fluids from one point to another.

Drawbacks

Do not have a high capacity

These pumps are not recommended by end suction pumps manufacturers in India for applications where large amounts of fluid needs to be moved.

They are not self-priming

Priming is the process of removing the air from the pump before use. Since end suction pumps depend on the rotation of the impeller to move fluid it becomes very important to prime the pump before use.

Impeller is prone to corrosion

The impeller of the end suction pumps can get corroded due to cavitation. Cavitation happens when the air makes its way into the pump. This can happen if it is not fully primed before increasing the speed or if vapour bubbles are formed due to high speed liquid. If cavitation is not checked in time it can lead to corrosion of the impeller.

Now that we have understood advantages and disadvantages of end suction pumps, let us study a little further about the different type of end suction pumps. There are mainly two types: Frame mounted end suction pumps and close coupled end suction pumps .

Frame Mounted End Suction Pumps

The shaft and the bearing are separate from the motor in a frame mounted design. The pump shaft and the motor shaft are connected with the help of a flexible coupling. Frame mounted shafts offer greater efficiency at lower cycle costs. This type of end suction pump is used in larger applications.

Also Read:- Advantages and Drawbacks of Centrifugal Pumps

Close Coupled End Suction Pumps

The pump and the shaft are one in a close couple end suction pump and the impeller is directly attached to the end of the motor shaft. This type of end suction pump is space saving and cost efficient. However, in case the pump experiences a seal failure, there is a risk that the motor could be damaged.

Comments

Post a Comment