If you want a specially designed system that works on the

principle of rotary movements to move fluid from one location to another you

can use Horizontal Pumps. Usually, it creates force with its movement to

move the liquid.

If you want to know more about them continue reading.

Through this article, you will learn about their working principle and other

characteristics of their different models, helping you to choose the right one

according to your needs.

The Working Principle of Horizontal Pumps

The Horizontal Pumps typically

have a fluid-dynamic design. This special design needs the system to be primed

first to work. This means that you will need to fill the system with liquid for

it to operate.

This addition of fluid is necessary to initiate the

impeller and accelerate it to ensure that the fluid flows outward from the

diffuser radially.

While generating energy for its operation, these pumps

typically work in two specific phases. In the first phase, the energy is

transferred to the fluid that is to be moved by using velocity to produce

kinetic energy.

In the second phase, the kinetic energy is changed to pressure

energy.

Diverse Range of Applications

The Horizontal Pumps have a diverse range of

applications. You will find it being used in:

·

Irrigation

sectors

·

Fire-fighting

systems

·

Mine

drainage

·

Artificial

snowmaking

·

Pumping

stations

·

Washing

and

·

Pressurization

installations.

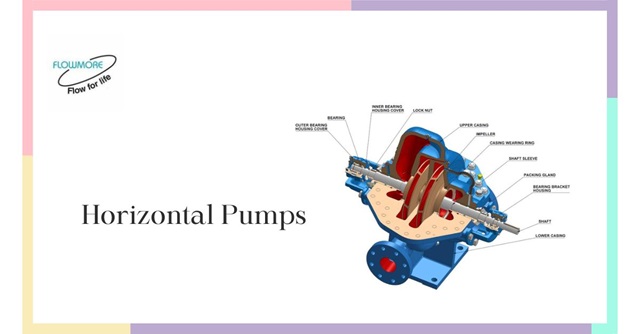

The Different Elements

There are different elements that make a horizontal pump.

These are:

·

The

housing to hold the other components of the pump

·

The

inlet valves

·

A

screen to protect the inlet valve from impurities

·

Impellers

having blades

·

A

safety valve to protect the system from water hammering

·

An

automatic valve and

·

A pressure

gauge.

Characteristics and Abilities

The specific characteristics of the Horizontal Pumps make

them useful for handling different types of fluids like water with high

viscosity values.

Also Read:- The Benefits of Horizontal Pumps

However, it may not work properly if there is air or solids

in the fluid or if the fluid does not tend to move even when the rotation speed

is high.

The main components of a horizontal pump are the volute and

the impeller.

The job of the volute is to collect and transform the continual

flow into a physical process to ensure a stable supply of energy. On the other

hand, the impeller rotates in a circular motion.

The Benefits

The benefits offered by the Horizontal Pumps. For

example, these allow the use of turbines and motors as rotation machinery due

to the large number of revolutions of the shaft.

The simple design and construction of these pumps make them

easy to use and increase and decrease power. These are cost-effective and

reliable solutions for an automatic control system allowing drawing fluid to

greater heights.

Conclusion

These pumps usually have a diverse range of applications,

including building construction, industrial processes, and agriculture. It is

the special design, different features, shapes, and sizes that make these

machines useful for different purposes. These machines are pretty easy to use

and are quite indispensable.

Comments

Post a Comment