The popularity of horizontal split

case pumps has increased recently, mostly because of their much lower cost as

compared to long-stroke and vertical pumps. Horizontal split case compressors

are referred to by several names, including "splitter" and

"dipstick." A split case pump is an axial type of centrifuge that is

distinguished by having its shaft housing the pump case in the exact same plane

as the pump's axis. Another term for this type of centrifuge is a split case

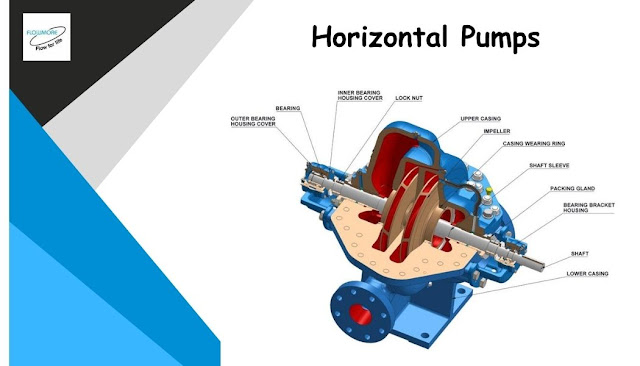

centrifuge. These Horizontal Pumps

often feature a unique design where two sides of the casing that would normally

be physically separated by a space are connected by a pump ballast.

Importance of using horizontal pump

A number of significant benefits

emerge when comparing the horizontal split case pump to the more conventional

design seen in vertical and long-stroke pumps. There are several advantages to

disengaging the impeller housing and motor housing connection. First off, this

makes it easier to remove the impeller housing and motor housing from the pump

directly. This makes it possible to remove dirt and debris from the system,

which raises the pump's performance and lengthens its life.

The horizontal split case pump also

has the advantage of being more efficient than other traditional designs. The

horizontal split case pump can achieve a substantially higher maximum

performance than pumps with alternative design concepts because it can

accommodate a greater capacity per square inch. Moreover as per the Horizontal Pumps Manufacturer horizontal

split case pump may function at temperatures much lower than those of other

pumps thanks to its increased flow capacity.

The horizontal split case pump can

therefore be used in a wide range of refrigeration applications; in fact, it

can work well in situations where other pumps are rendered ineffectual. The

fact that these pumps can run at a lower pressure because of their higher flow

capacity is another element that adds to their increased effectiveness.

You should be aware of the

following few drawbacks with horizontal split case compressors, though. The

main difference is the increased amount of space needed to accommodate the

motor housing and the pump. In addition, the dimensions and shape of the

housing have been purposefully designed to endure a wider range of vibrations.

The case's horizontal orientation raises the likelihood that it may corrode and

experience corrosion-related damage. Moreover, the increased turbulence within

the enclosure causes the frictional resistance that the impeller shaft

encounters to increase proportionally. This causes the pump to fail too soon

and lose some of its effectiveness.

Split-Case Pump Implementation Benefits

The goal of split-case pump design

and development has been to achieve extraordinarily high efficiency levels.

This makes it possible for these pumps to function at low to medium discharge

pressures, making it easier to handle large amounts of fluid. Furthermore,

split-case compressors have incredibly efficient operation.

Split-case centrifugal Horizontal Pumps India

have very simple maintenance procedures because of the way they are

constructed. Because of the way these pumps are made, it is easy to reach the

impellers and other internal parts. As a result, split-case centrifugal

compressor maintenance requires a significant reduction in both time and labor.

Compared to alternative pump types,

split-case pumps produce noticeably less noise and vibration. This is made

possible by the impeller being mounted to a shaft that has two bearings

supporting it, which helps to reduce noise pollution.

The final sentence

A dependable and multifunctional

pumping solution by Horizontal Pumps

Manufacturer India, the split-case pump is widely used in a variety of

industries, including municipal, commercial, and industrial. This product's

design ensures consistent and efficient fluid transfer while making repairs and

maintenance easier with its separated casing and impeller. A split-case pump is

useful in many different applications, including mining, agriculture, water treatment

facilities, industrial production, and fire protection. Owing to its capacity

to withstand high pressures and prolonged periods of continuous operation, the

split-case pump is a vital component of numerous different systems. Its ongoing

use is anticipated to last for the foreseeable future as a direct result of

this.

Comments

Post a Comment