You can use PROPELLER PUMPS in

different settings where you need a high flow of fluid. These pumps usually

have a linear path of fluid flow and a low-lift impeller. The best thing about

the feature of these specific pumps is that you can set them in any orientation

you want.

You can set it horizontally, vertically, or at an angle and

get the same results. This is because regardless of the orientation of the

propeller pumps, the impeller stays below the water level and the motor above

it.

The Basics of Propeller Pumps

Here are a few basic aspects that you should know about the

PROPELLER PUMPS.

Working principle:

The working principle of these specific types of pumps is

based on the impeller head. This impeller is specially designed with a

propeller blade which facilitates the drawing of water out of the discharge

outlet and up the outer casing.

While operating, the pump draws water using the rotating

impeller. The water usually moves straight up the casing and can even move up

through the discharge pipe which is usually angled.

Usefulness:

The usefulness and design of the PROPELLER PUMPS make

them useful for different applications including chemical plants, water

treatment systems, agricultural applications, and other settings where you do

not require a high head value.

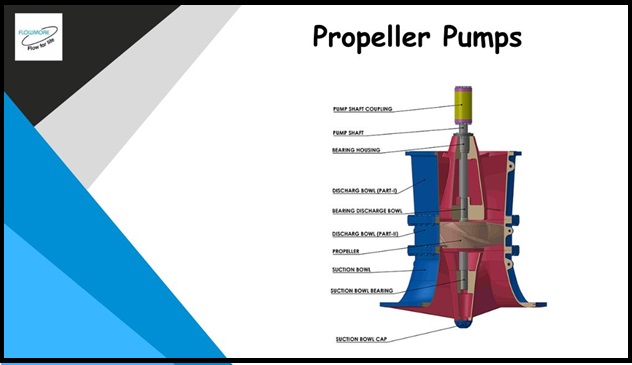

The Design

The design of the angled and vertical PROPELLER PUMPS allows

the drive motor to stay above the water level. This is located on top of the tubular

casing.

The shaft of the pump drive however runs down to the bottom

to reach the impeller head inside the casing. There is a sealed tube inside

that holds the specific types of bearings for support.

In addition, the impeller of these pumps is specially

designed as well. These have rotating blades that resemble a propeller, which

is why these pumps are called PROPELLER PUMPS. This unique design helps

in transferring liquid easily through the pump.

There may be one or several stages of it depending on the

specific design. This eventually determines the performance of the suction head

located in the casing housing the impellers.

These impellers usually are installed by a strainer

attachment. This prevents entry of unwanted foreign objects into the system.

Different Applications

Depending on the setting and design of the propeller pumps,

the application may vary.

For example, if you use it as a horizontal propeller pump,

you can use it for drawing water through a bulkhead or reservoir wall since the

motor is watertight and can stay submerged.

If you use a mobile unit, such as the free-floating variant

of these specific pumps, you can use it on a purpose-built pontoon and move

around the water body as desired.

If you use angled pumps, you can draw water from reservoirs

that have steep, inclined walls.

Conclusion

Compared to other pumps, propeller pumps can offer a large

number of benefits. These machines do not need prior priming to operate, can

handle large flow requirements, and can also pump out suspended sand.

Comments

Post a Comment