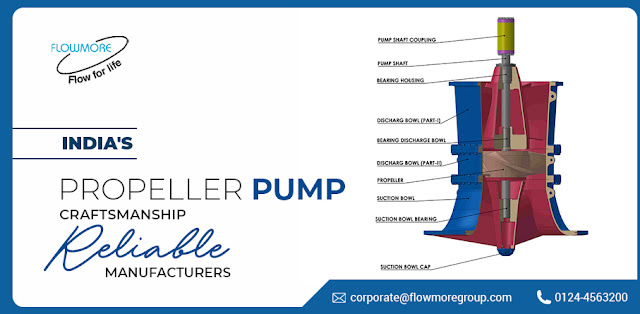

Propeller Pumps

manufacturers, exports, and distributes numerous industrial pump types. It

includes Polypropylene process pumps, self-priming centrifugal pumps, and

polypropylene pumps. These are just a few. All of the diverse needs of a large

range of industries. It includes waste water treatment, engineering,

transportation, pumping equipment, sugar manufacturing, and many more.

Several Requests

● Managing agricultural land with irrigation and drainage

● The primary purpose of Propeller

pump and pump stations is to regulate the water level.

● Sewage treatment systems require water circulation as a

fundamental component.

● Increasing the oxygen content of water sources used for fish

farming

● Tankers, ferries, and ships all need to be rigged.

● Docks built near bodies of water may flood or drain.

● The process of filling or emptying tanks

Water might have anything from

zero to fifty milligrams of solids per liter. It happens depending on where it

comes from. Freshwater, saltwater, and brackish water are a few types of clean

water.

Mid-range temps that pump up to fifty degrees Celsius

Our team of skilled engineers

designs and fabricates industrial pumps to rigorous standards in a range of

capacities and technical features in response to specific customer

requirements. They are able to achieve this because of their extensive industry

knowledge and proficiency. Flowmore Limited has established a close-knit

community of Propeller Pumps Manufacturer

India in order to improve the lives of the clients and the

efficiency of the pumps.

The decapitations

● Centrifugal force pumps with a single stage, an open semi-axial

impeller, and

● Water-resistant motors having an IP 68 rating that can be filled,

rewound, and submerged

● Moreover, a very efficient and reasonably priced permanent magnet

synchronous submersible motor is already available on the market.

● A mechanism that circulates fluid around the motor to cool it

Water-lubricated axial and radial sliding bearings

● The motor is protected from the outside by a mechanical seal.

● The volume-compensation system loads the motor to its maximum

capacity.

● Powered cable with a watertight connection and a rubberized

coating

● Three modes of operation are possible: continuous, switching, and

frequency control.

● To put it simply, human function is made possible by the frequency

converter.

● The two processes carried out concurrently

● Use of premium materials in the water transportation, industrial,

and service sectors

Numerous benefits

● Positioning the installation, whether vertically or horizontally

● The pump can be operated in a back-to-back or submerged tandem

arrangement, or it can be run straight.

● The pumped medium that surrounds the water-filled motor and its

superior cooling characteristics.

● The rewindable motor's mechanical feed-through to the external

environment is stopped by a shaft seal.

● The frequency converter enables modifications.

● Long intervals between maintenance requirements

● Little maintenance costs

● The facility is 100% recyclable. It has low operating costs. It is

environmentally friendly.

Fully network-based services

There are a few things to

consider. This is when looking for submersible pumps. It is crucial to

determine the kind of submersible pump required. This requirement is for the

specific application before proceeding. Numerous varieties of pumps are

available on the market. Each pump has special qualities and benefits of its

own.

The next thing to do is

evaluate the costs after you've chosen the kind of pump you want to purchase.

This is offered by various sellers to find the best deal.

You should consider both the

cost and the caliber of the service when selecting a supplier. Only purchase

pumps from a business that has a track record of making high-quality products.

It would be better if you didn't get a defective pump that couldn't work as it

should.

The

easiest method to ensure that the Pumps

manufacturer India you select, like Flowmore Limited, provides excellent

customer service is to verify this information. Important information to have

on hand in case you have questions or concerns about the pump after

installation.

Comments

Post a Comment